Multi-process handling operations with Agent Model design

- Home

- /

- Best for You

- /

- Multi-process handling operations with…

1.Difficulties in designing multi-process handling operations

One of the goals of manufacturers is to create a production line and system that achieve stable and efficient production. One approach to achieving this goal is to utilize the flexibility of workers’ behavior.

As we all know, nowadays, the trend toward multi-product production and labor-saving is effective to increase the overall production efficiency of a production line by having each worker take on multiple tasks.

However, it is not easy to evaluate and implement the process design of who should be assign to what job, with what skills, when, where, and how to improve production efficiency objectively and accurately.

It is certain that “Standard Operation Combination Table” or “Cycle Diagram” are often used to design multi-process handling workers, but it is very time-consuming when drawing charts using EXCEL or other software.

Moreover, it is a difficult task to design not only a simple man-machine operation but also to consider the entire flow under complex conditions, such as when a worker is assigned to work at multiple stations. On top of that, there are many things to be verified, such as cycle time variations, short-time breakdown, walk speed, and skill differences.

Therefore, in a production line where many different types of products are manufactured, the process becomes more and more complex and beyond the capability of human beings (the limit of EXCEL).

If the know-how for designing multi-process work is to be a means to achieve stable and efficient production, it is subjective and not effective. Even if productivity improves as expected, the evidence is unclear. Then, it is no longer possible to achieve the goal of improving productivity through implementation, which is a problem shared by many manufacturers.

2.An approach to multi-process worker’s design

The reason why multi-process handling design is difficult is that it is impossible to design the workflow relying only on EXCEL and charts because of the relationships between machines and workers, workers and workers, front-end process and back-end process, etc. There is a limitation of incorporating the actual worksite into the chart with imagination since it is difficult to design a series of processes comprehensively or to write a static chart of a dynamically behaving workplace.

An effective approach to this issue is to conduct virtual experiments using production simulation. You can understand at a glance how effective your design and assumptions are and where the problems lie by “trying” What-if scenario. Virtual experiments on simulations can be conducted without any cost. Therefore, it is permissible to conduct repeated virtual experiments.

*The “cost” here means the time charge for the process design.

3.An approach to multi-process worker’s design

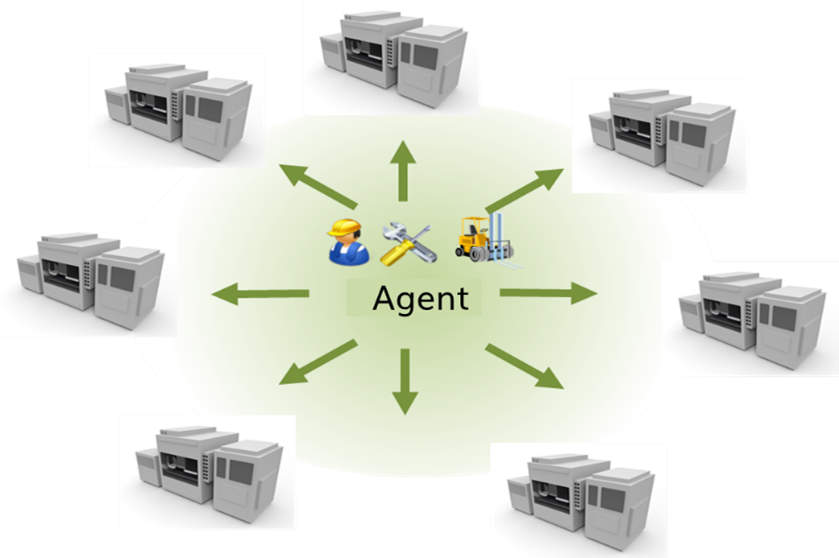

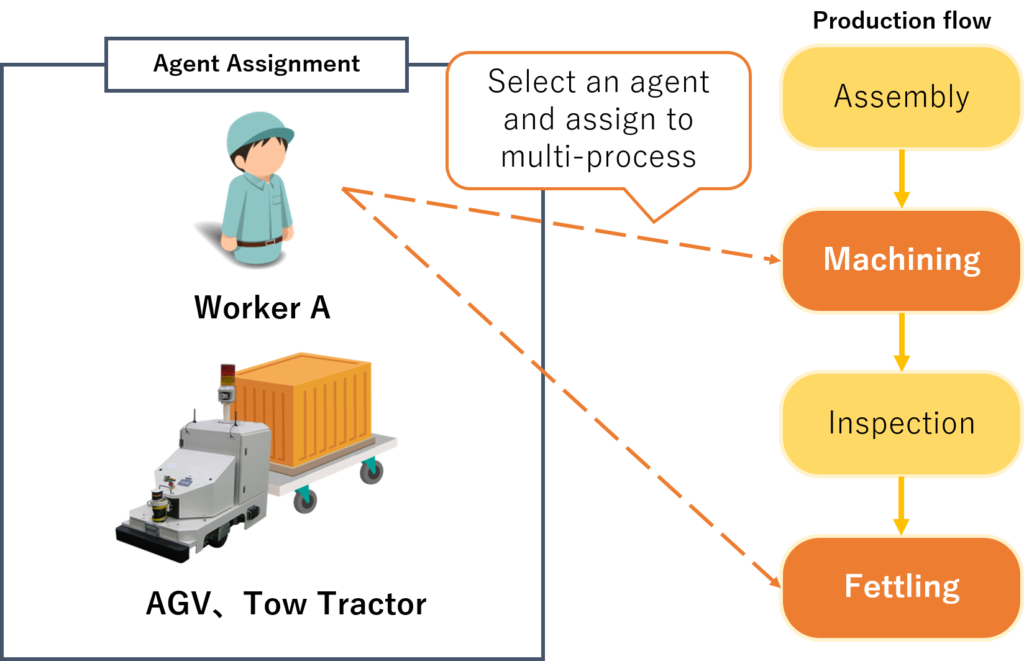

One of an unique features of GD.findi is its “Agent Model” design function.

An agent is considered as an asset (worker, AGV, etc) that can define its responsibilities and it will act based on its own judgement of the situation.

In Agent Model design panel, you can create a “Worker” agent that performs multi-process tasks.

With GD.findi, you can reproduce the multi-process design under any conditions repeatedly. You can confirm the stability of the production by analyzing the outcomes of the successful design plan. On the other hand, if the design plan does not work, you can evaluate the causes and try a new concept.

Moreover, by specifying the parameters of problems that may occur, it is possible to reproduce complex multi-process operations and meanwhile troubleshooting in the simulation. Then, finally, visualize the overall realistic movements of the production site.

4.Worker Agent Behavior

Here is the description of how worker agents behave when assigned as multi-process handlers in GD.findi.

The worker agents act when a workstation sends out a command to those who are assigned to the task when an activity(action) occurs, such as the start or end of a machining process. Then, when this command is sent, the workstation will grab the available/closest worker agent to perform the necessary task.

Meanwhile, if all the assigned worker agents are busy when the command is sent, the workstation will wait (stand by) until worker agents finish their current task.

Then once a worker agent is free, it engages with the workstation’s task. The time that the workstation spent waiting until a worker agent arrived can be reflected in the GD.findi simulation.

Video 1. Worker Agent Behavior

5.Set up and run the Worker Agent

In GD.findi, the tasks to be simulated are registered in the “Station Activity” panel, which holds the relation(data) between workstations and work elements (process). Once the layout (floor plan) and the work elements(process) has been set up, Station Activities are automatically displayed in a list as shown in the figure below. See figure 4.

Worker agents are easily defined in this activities panel, you can select an agent from the asset assignment list and assign it to multi-process operations.

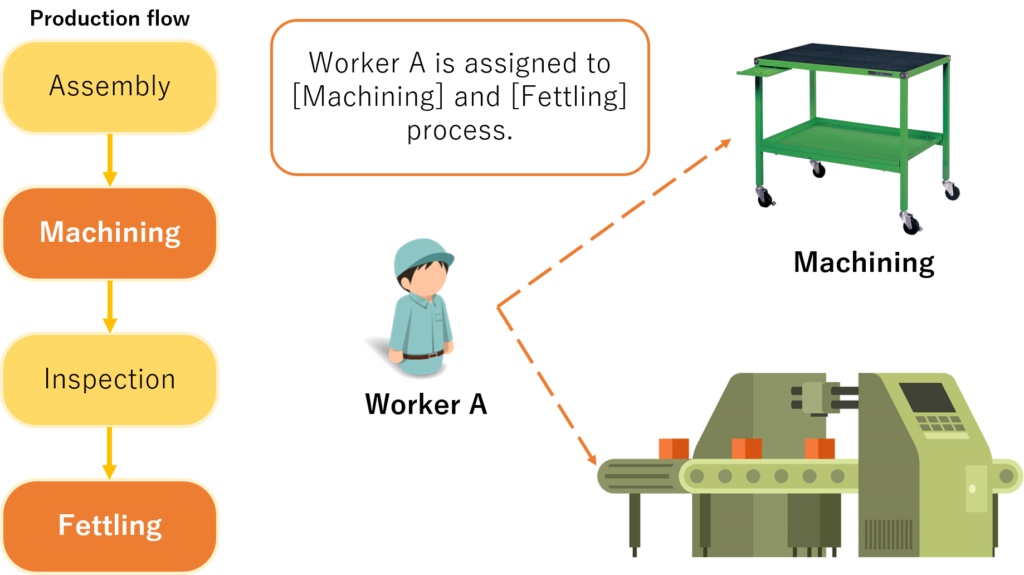

In figure 5, “Worker A” is assigned to two tasks, “fettling” and “inter-process”, which means that Worker A will in charge of multi-process handling for these two tasks.

By this simple setup method, the behavior of the multi-process handler is immediately reflected in the simulation.

Video 2. Multi-process handling worker’s behavior

6.Worker Agent’s as a Group

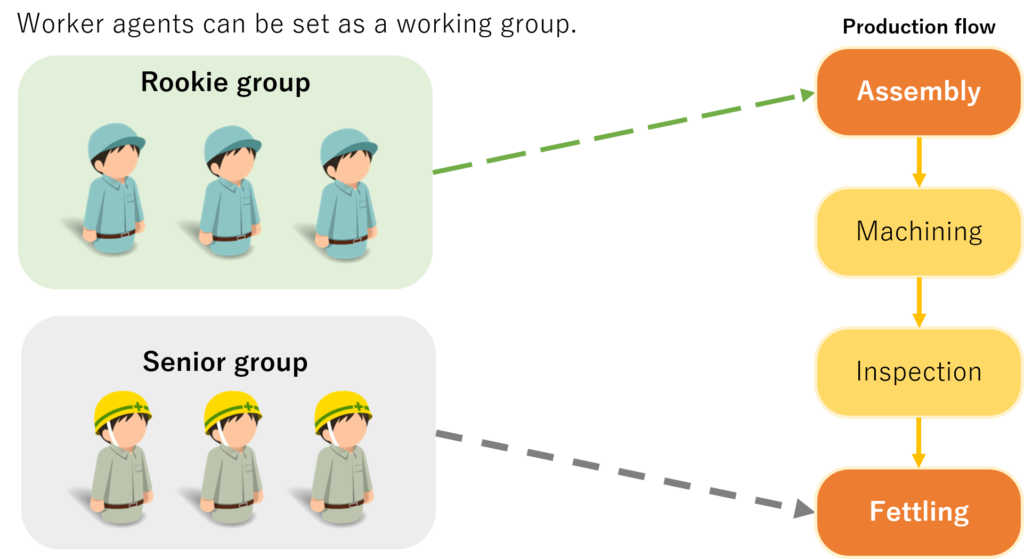

Next, a worker agent can be set not only as an individual worker but also as a working group. That also means station activity can be assigned to a working team with multiple workers.

With this grouping allocation function, it enables designing work assignments based on the skills of the workers. It is also possible to set the walking speed of worker agents, etc. See figure 6.

7.Decide the optimal number of workers with Worker Agents

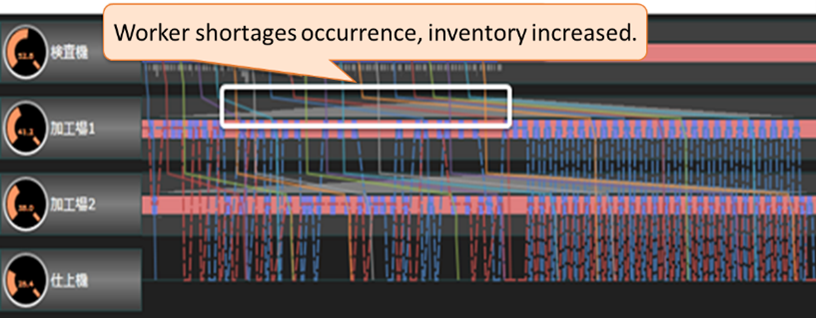

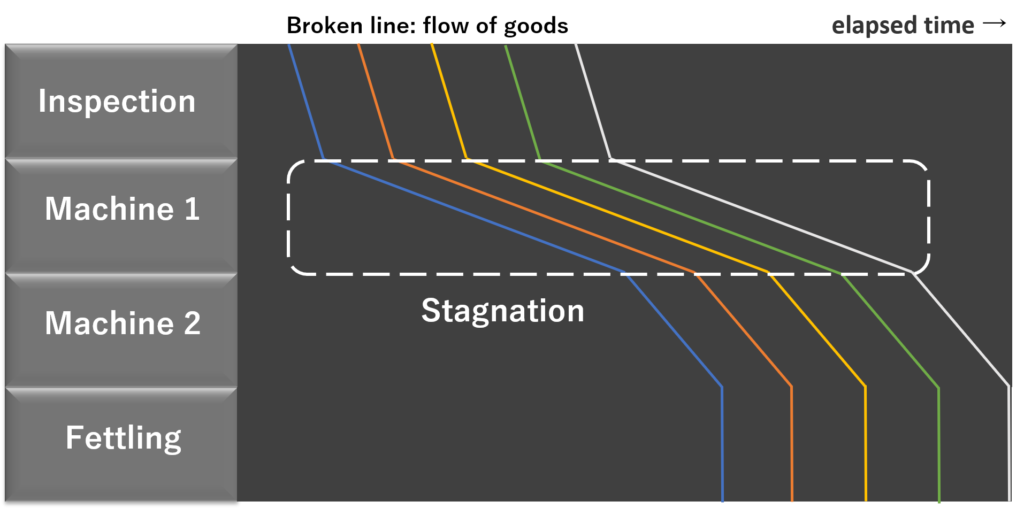

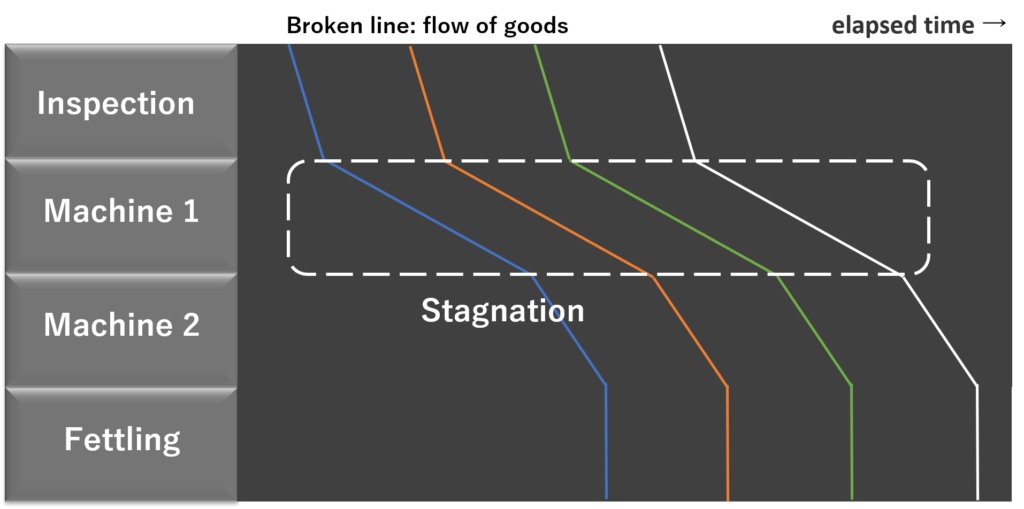

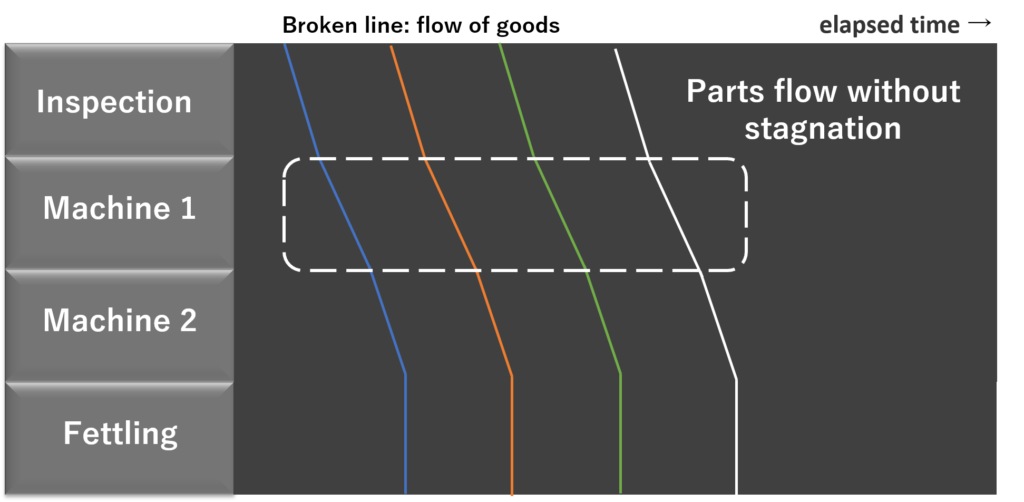

It is often difficult to decide the number of workers in a multi-process production line. For example, the process can be delayed or stopped because of the limited number of workers, it results in losses such as inventories overwhelmed between process, etc. In GD.findi, such cases can be diagnosed with the result analysis tool: “Material Flow Chart”. See figure 7.

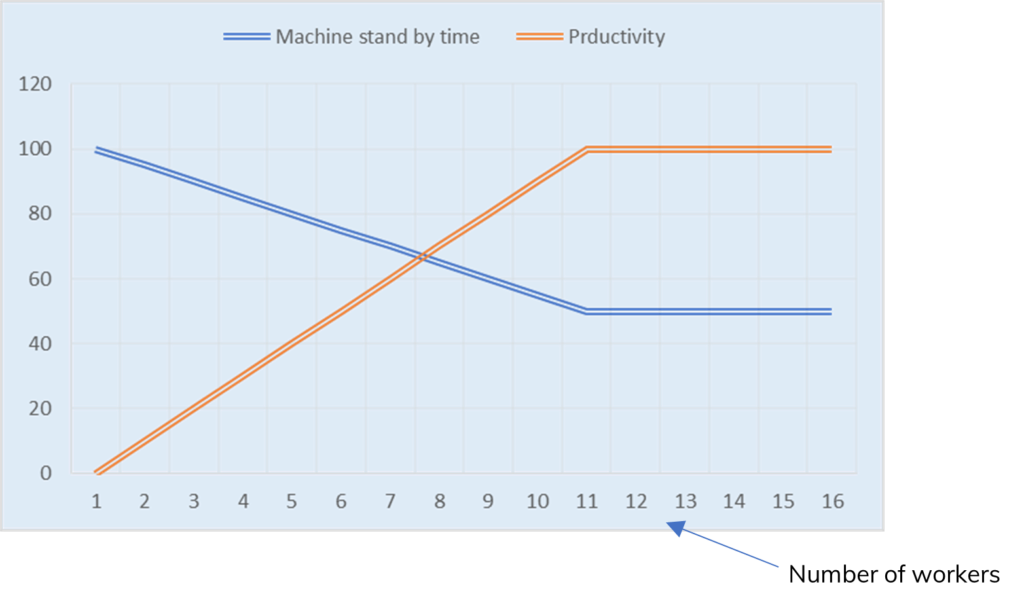

Moreover, with this feature, you can find the appropriate number of workers without labor waste by changing the parameters in the Agent designer panel.

In other words, you can continuously increase/decrease the number of personnel in the worker agent group to find the number of workers that give the best production outcome.

In other words, you can continuously increase/decrease the number of personnel in the worker agent group to find the number of workers that give the best production outcome.

By looking at the figure above, we can consider figure 10 has the highest productivity with a minimum waiting time (stagnation).

With this method, worker agents can be used to optimize the design of multi-process handling workers with complex behavior. Additionally, we can understand the behavior of multi-process workers in a multi-dimensional way objectively and evaluate them accurately.