GD.findi Data Model

- Home

- /

- Technologies

- /

- GD.findi Data Model

GD.findi Data Model

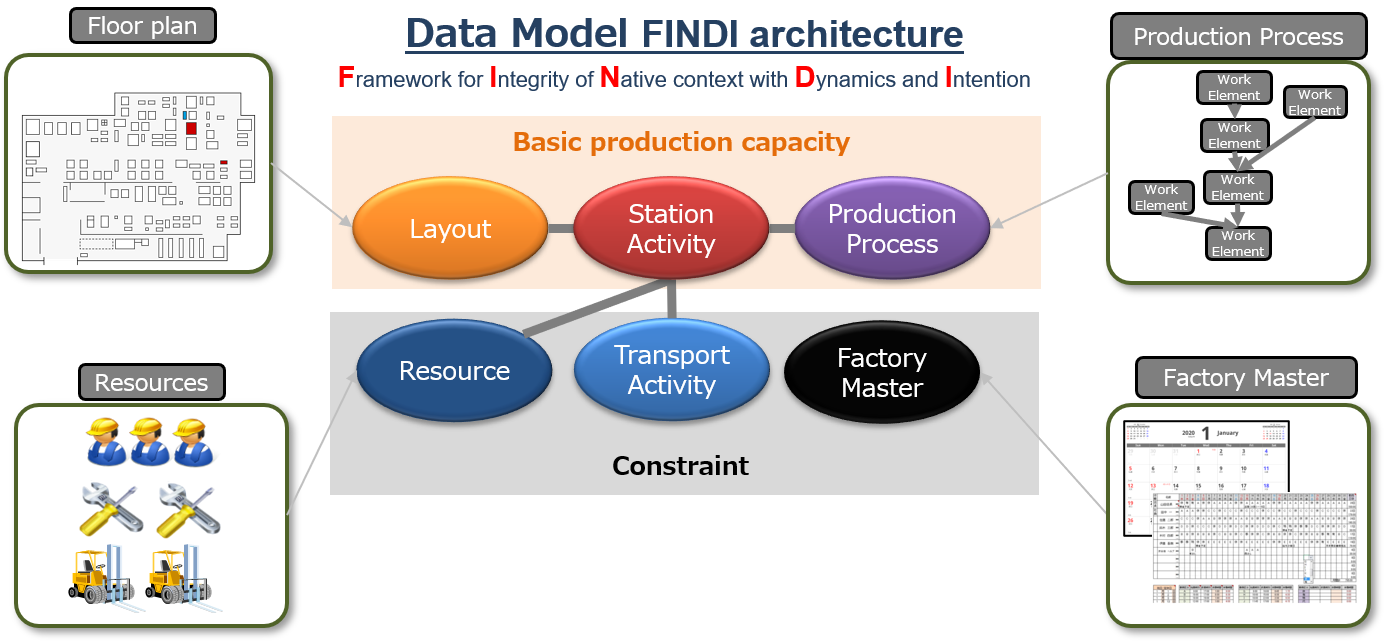

The six components defined in the data model, and the types of parameters that can be set for each component, are shown below.

Components that define basic production capacity

By setting up the layout, station activity and production process components, theoretical production capacity of the factory can be defined.

Layout component

It consists a group of information that defines layout properties.

It configures the location of equipment or workstations, as well as the maximum quantity of inventories can be stored before each workstation.

Production Process component

It consists a group of information that defines production flow and working hours for each final product. It configures information such as process flow, MBOM, and standard working hours for each process in a production line.

Station Activity component

It consists a group of information that set up correlation between workstations and operations. For example, what operation is to be performed at which workstation by whom(worker). Production capacity of workstations can also be defined.

Information that acts as a constraint

The Resource, Transfer Activity and Factory Master components enable setting constraints in GD.findi. In addition to the basic production capacity, the constraints can virtually define dynamic production activities to present various conditions that is possible in the factory.

Transport Activity component

This is a group of information that defines transport activities from the front-end process to the back-end process. Information such as the transport time required to deliver products and workers who perform the transport activity is configured.

Resource component

GD.findi considers workers, AGVs, and molds/dies attached to an equipment as factory assets. A resource component is to configure all the possible information to be set as an asset in a factory.

Factory Master component

This is a group of information that defines working hours, holiday calendar and production index. The factory master is used to configure all the above information into GD.findi factory.

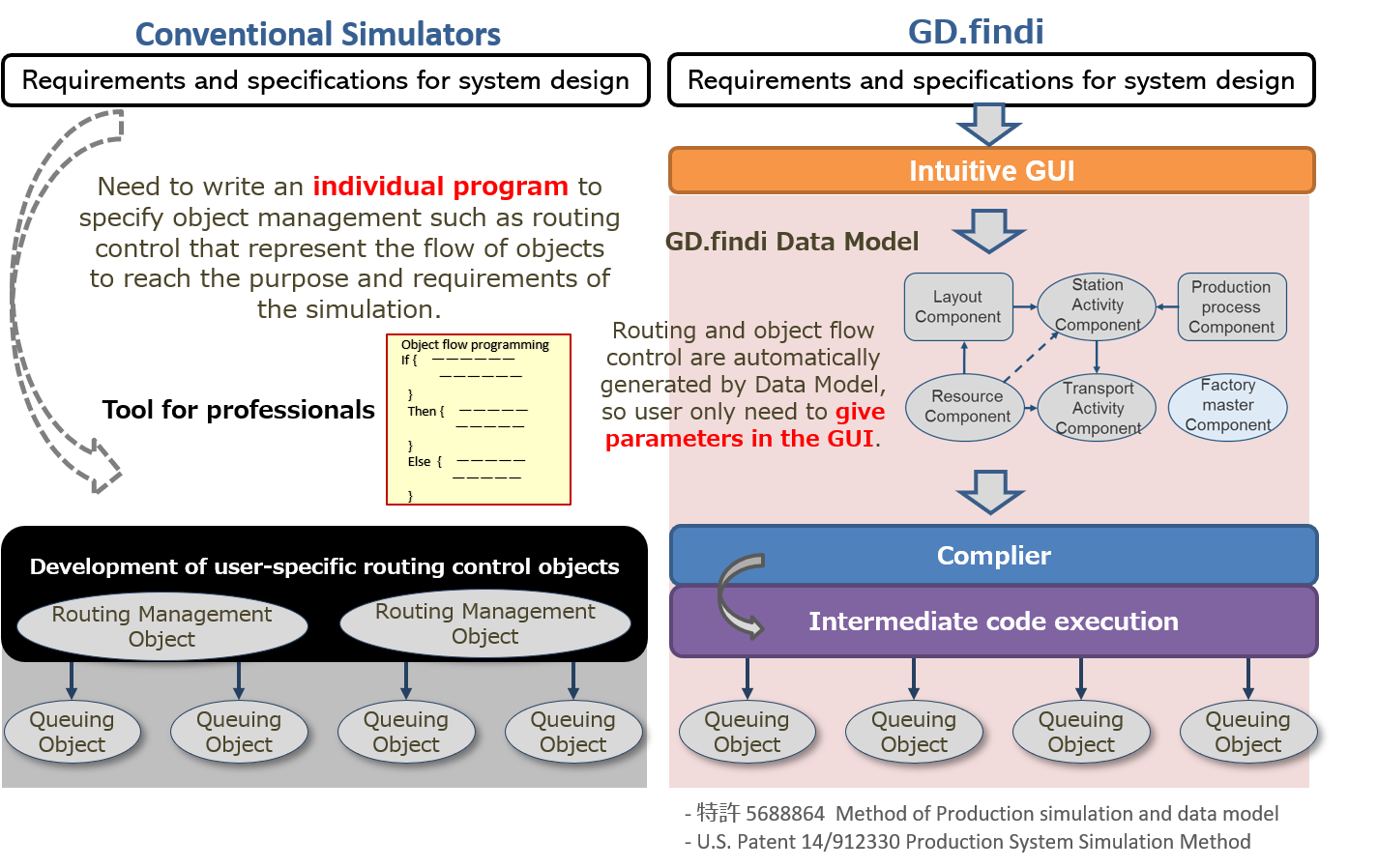

What makes GD.findi different from conventional simulators

The difference between conventional simulators and GD.findi lies in their modeling methods. While the conventional transport simulators is about defining the production flow in programming, GD.findi refers to editing the values of the parameters contained in components defined in the Data Model.

Conventional Simulators=Tool for IT professional

Modeling

It requires specialized programming skills and a certain amount of time to practice modeling.

GD.findi =Tool for product engineers/managers

Modeling

(No programming required)

Speedy modeling is possible by simply editing the parameter values in Data Model. No technical knowledge is required.

GD.findi simulation is formed with queueing objects to be processed represent by “Queueing Theory”. This is similar to conventional simulators, however in conventional simulators, the object is generated by individual programming. Therefore, although detailed simulations are possible, it requires programming skills and time.

On the other hand, in GD.findi, the logic to form a queueing object is defined in Data Model in GD.findi internal program. This allows users to generate queueing objects by simply editing the values of the parameters contained in each component defined in the Data Model, making modeling fast and easy.

For product information about GD.findi MS, a production system simulator that utilizes GD.findi Data Model, please click the following button.