Case: Pressed parts manufacturer Company T

- Home

- /

- Newsroom

- /

- case

- /

- GD.findi MS

- /

- Pressed parts manufacturer Company...

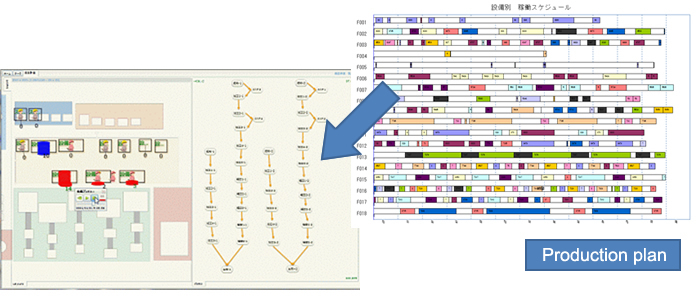

Use of simulations for production plan drafting work

Company T is engaged in the manufacture of high precision pressed parts. However, it is dependent on a limited number of planners. That is because drawing up the production plans for the types of press lines required in order to be able to respond to small-lot orders from various manufacturers of assembled products is an extremely complex task. When formulating production plans that cover both retooling work and employee assignment, it is a very time-consuming process to be able to ensure that these production plans are indeed viable. Enhancement of productivity, operating rates, TAT (turn around time), etc., requires a wealth of experience and professionalism, as well as considerable investment of time. In response, the company introduced Lexer simulations and is now drawing up its daily production plans by using data in the EXCEL format as the basis for carrying out simulations.

In this way, by carrying out production plan simulations it is able to ensure that there are no problems with the plans (in terms of repetition, negligence in following a plan, etc.), and also determine what the operating rates for various facilities would be. Furthermore, because of the ability to verify instantaneously that there are no problems with areas like work in process, it is therefore in a position to incorporate this data into better-fashioned plans, while other staff members are also able to efficiently formulate plans.