FAQ

FAQs about GD.findi operation

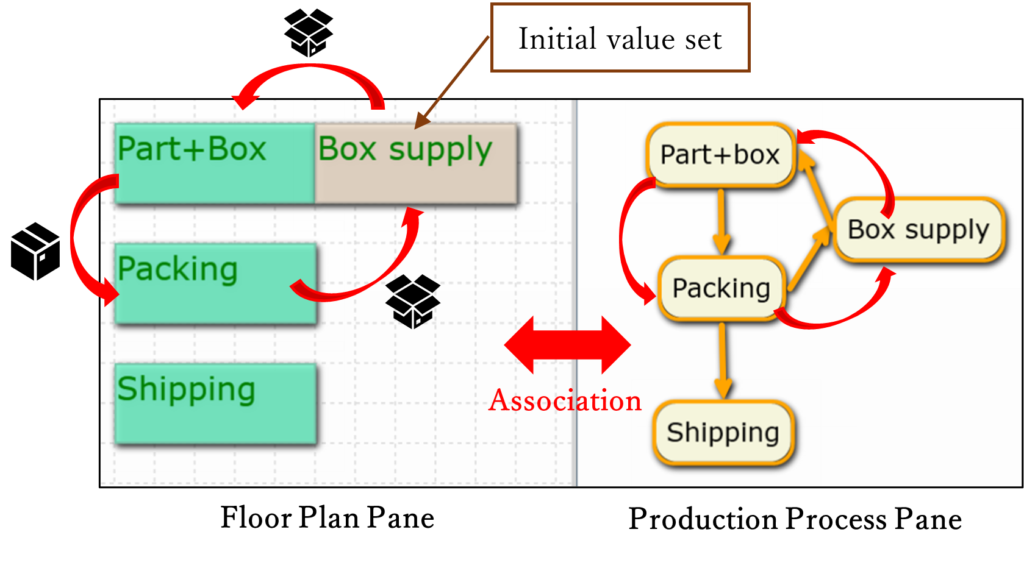

To express a reusable item in GD.findi, first, set the item as a “part” in the production line. Then, in station parameter panel, set the initial value of the reusable part as “1”.

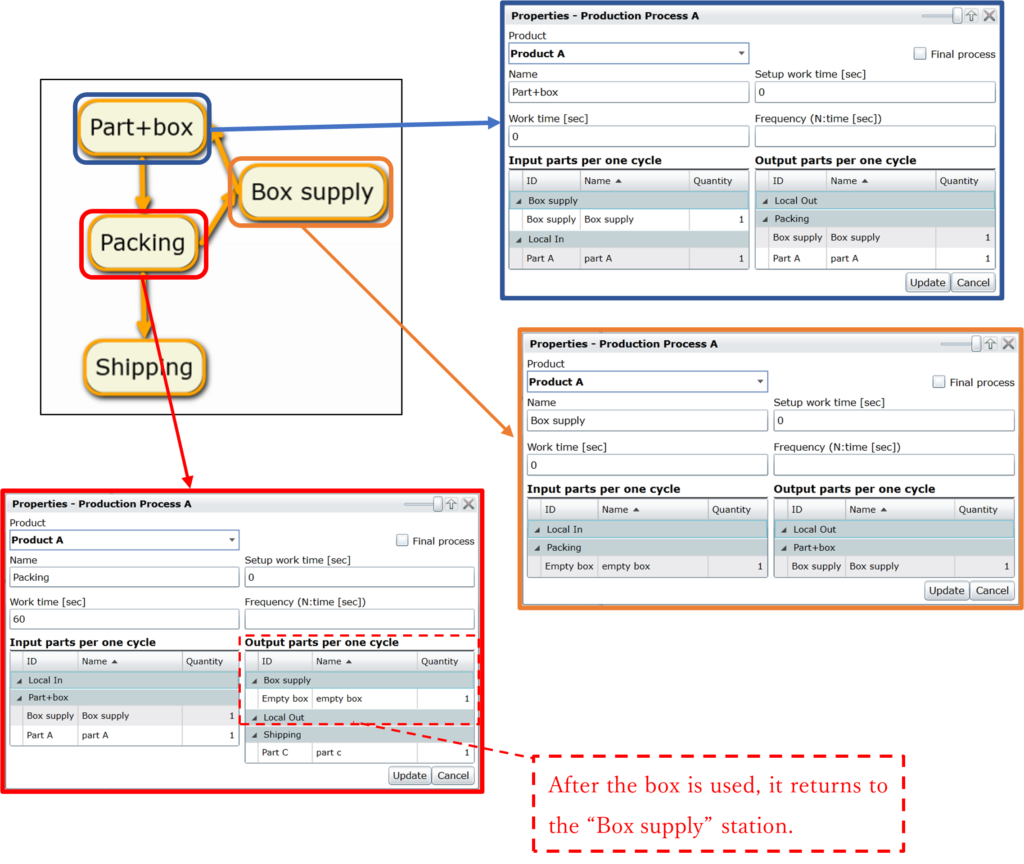

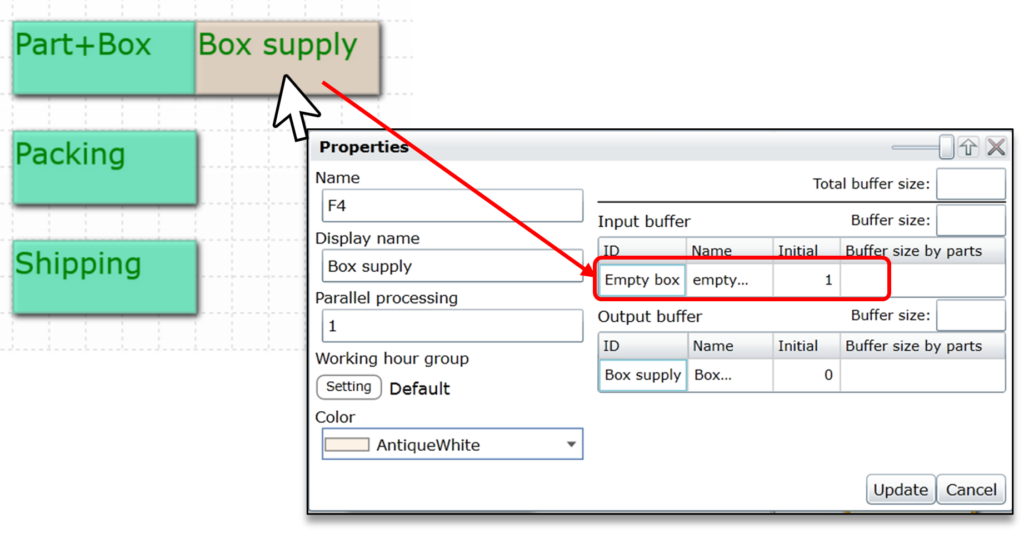

For example: create following production process and use a box as the reusable item. In this case, the reusable box is express by setting the initial part in a station properties panel.

| 【Memo】

・Setting an initial value express the items existence when the production activity starts. To be specific, when the box’s initial value is [1] means a box is standby at the workstations when parts are arriving. |

Example of how to set the input parts and output parts value in this case:

If an empty box is needed to start the production. Set the initial inventory of empty box to 1 in the input buffer for the station “Box supply”. Please refer to the following example.

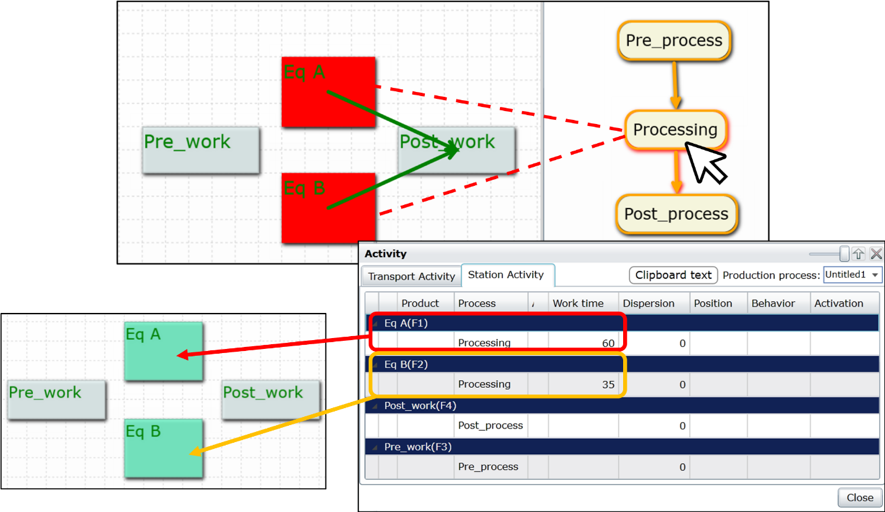

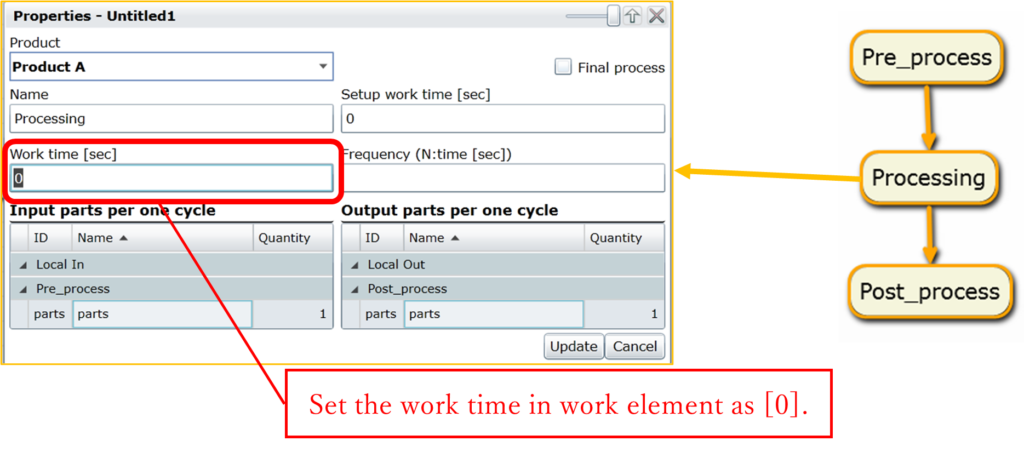

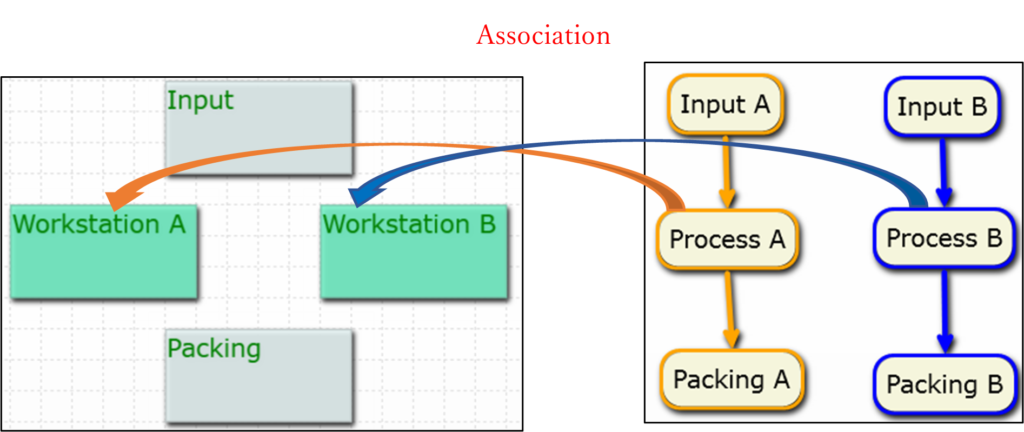

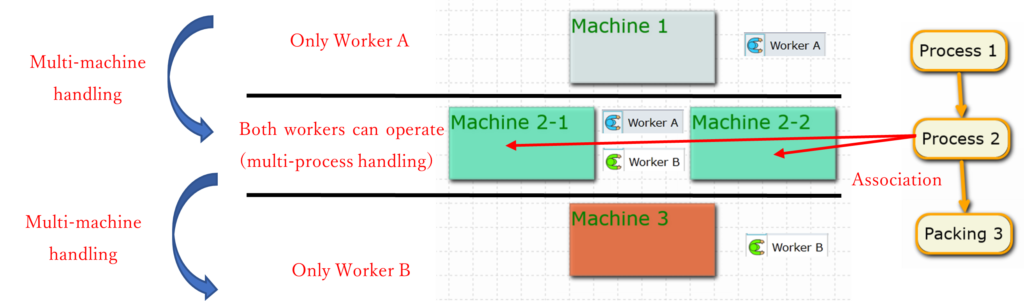

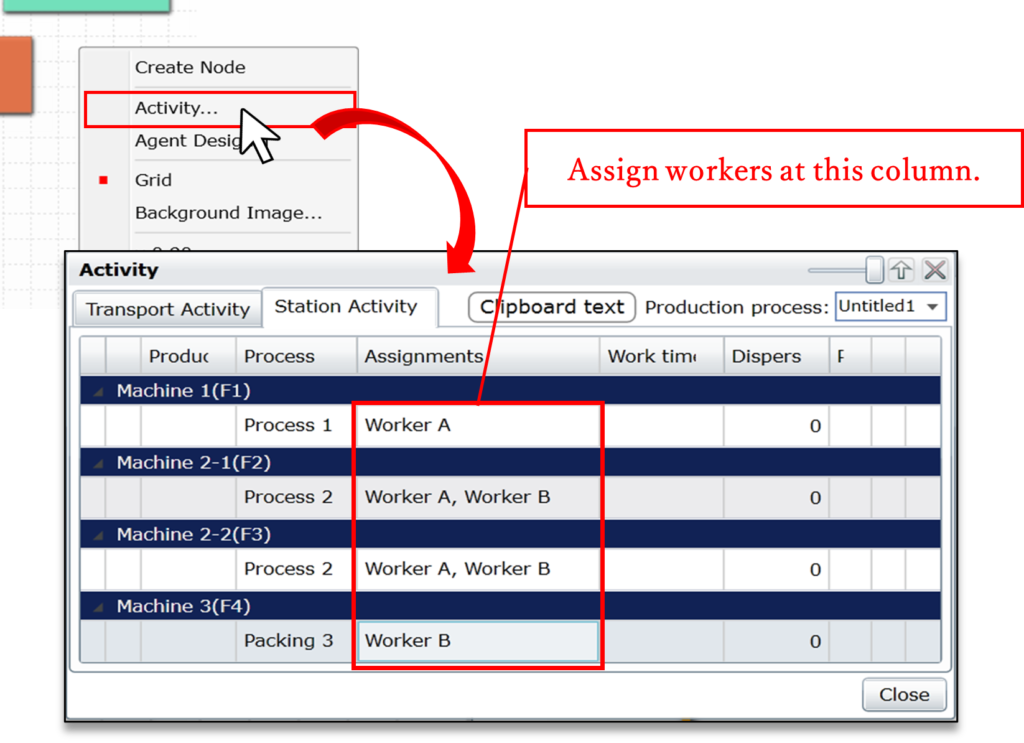

When there are multiple equipment with the same ability however each equipment has different work time. In GD.findi, you can first associate all these equipment with the same work element, then, set the different work time in “Station Activity” panel.

For example: Equipment A (Eq A) and Equipment B (Eq B) have different work time.

- Associate both stations with the same work element.

- In “Station Activity” panel, set the different work time for each equipment. In this case, please leave the work time in the work element properties panel as [0].

Note: The work time set in the station activity takes precedence over the work time in work element.

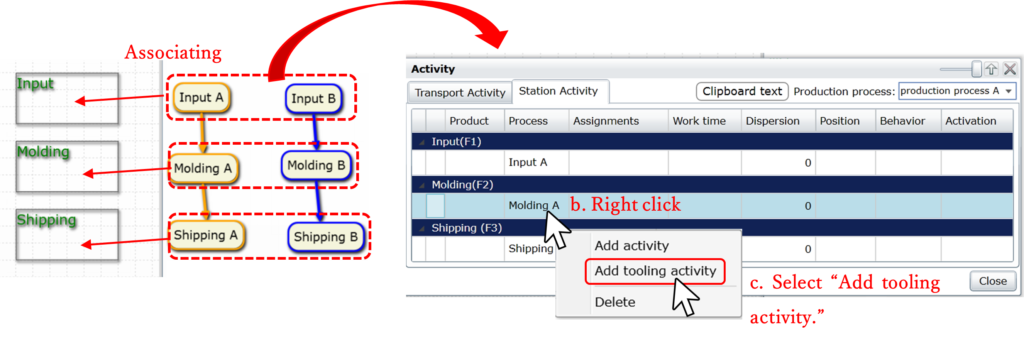

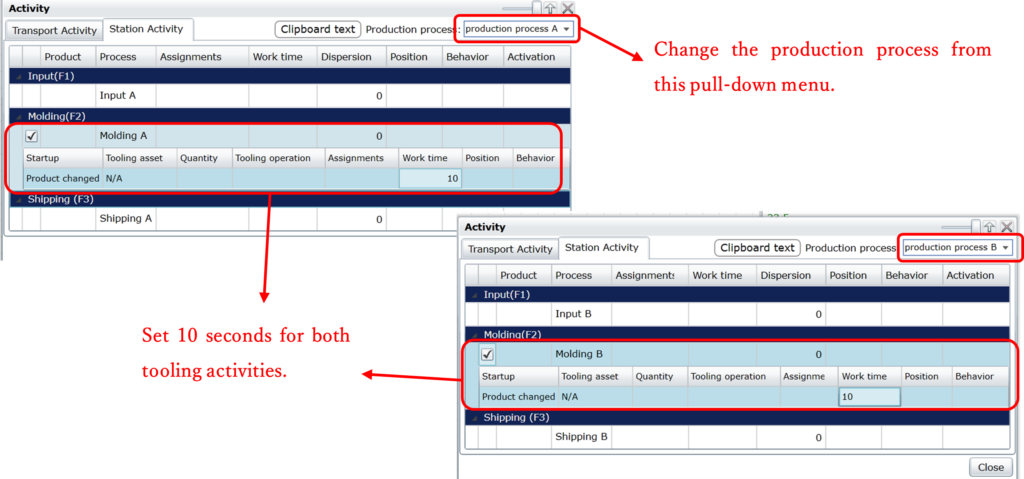

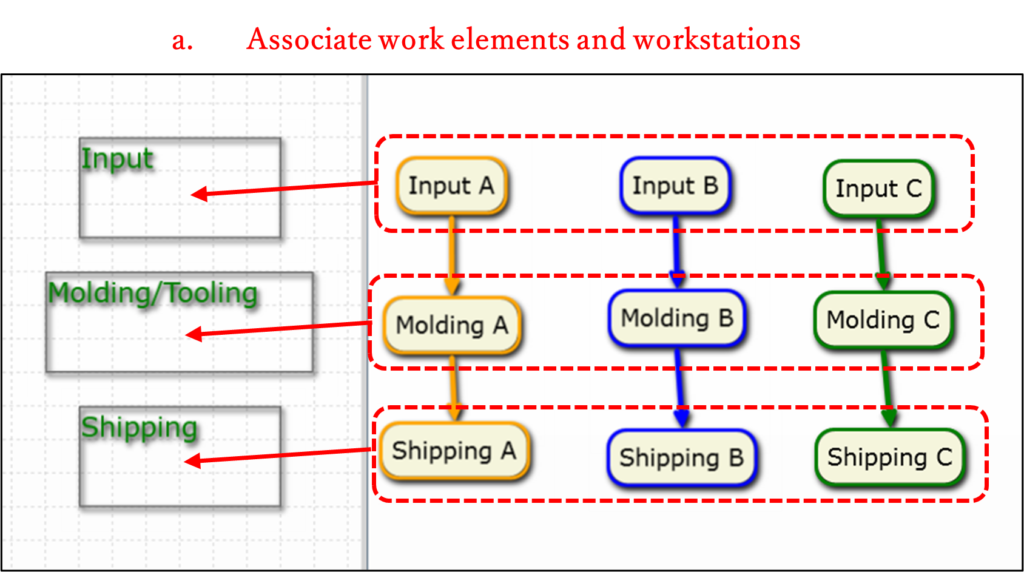

Station Activities allows you to express the changeover time by setting tooling activities in the workstation.

For example:

Product A → Product B, changeover 10s

Product B → Product A, changeover 10s

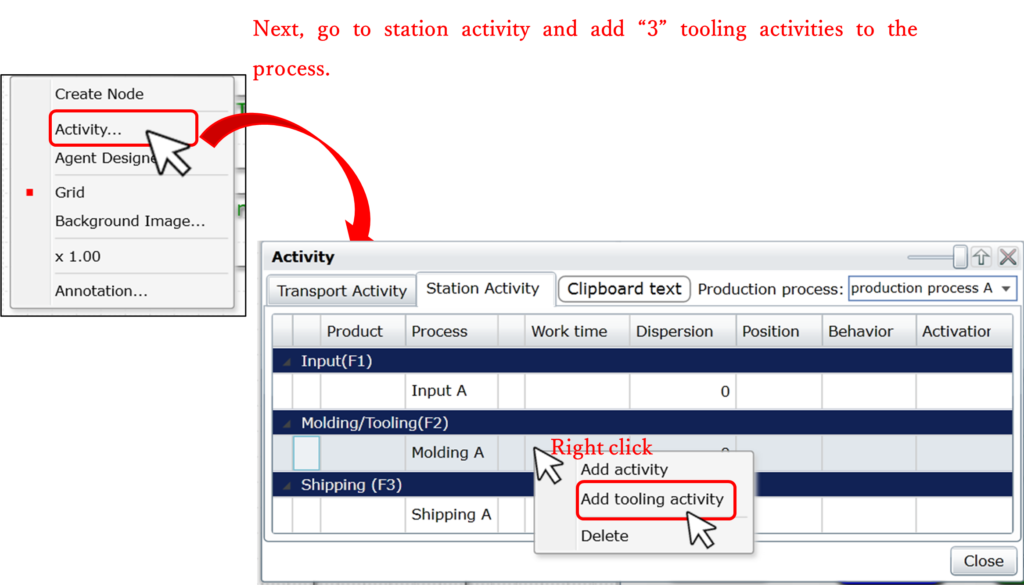

- When you want to set the changeover time like above, after associating work elements and workstations, please go to station activity panel and add tooling activities to the process you wish to add changeover time.

- If the changeover happens at the molding workstation, set 10 seconds tooling activity for both Molding A and Molding B process.

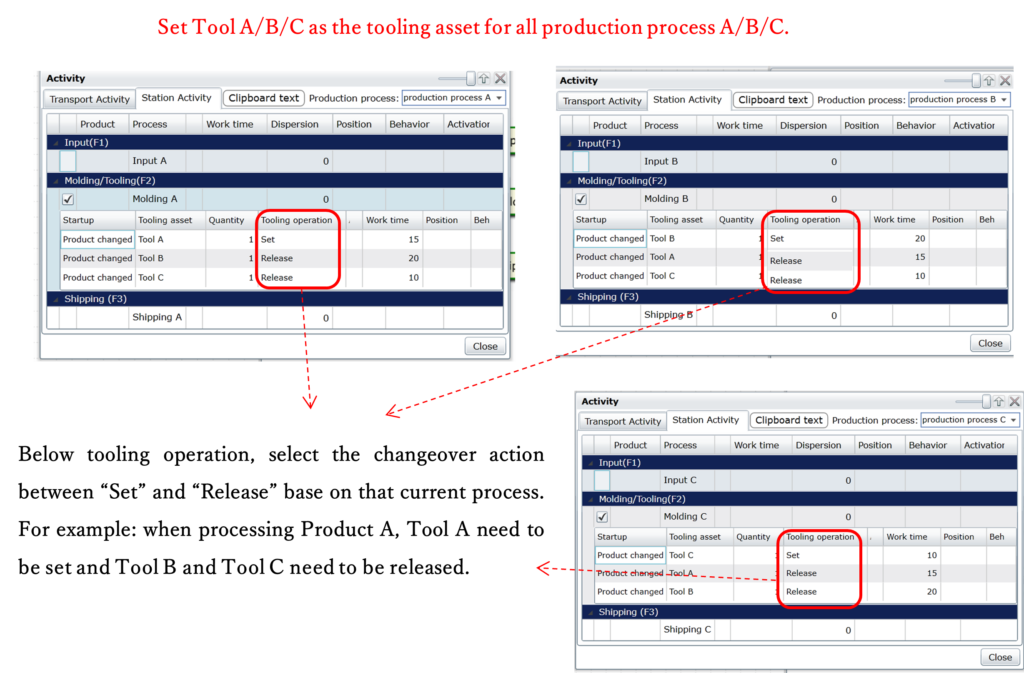

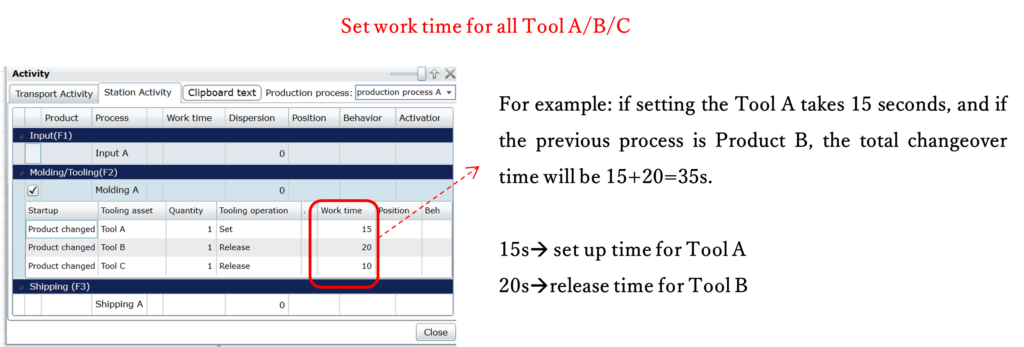

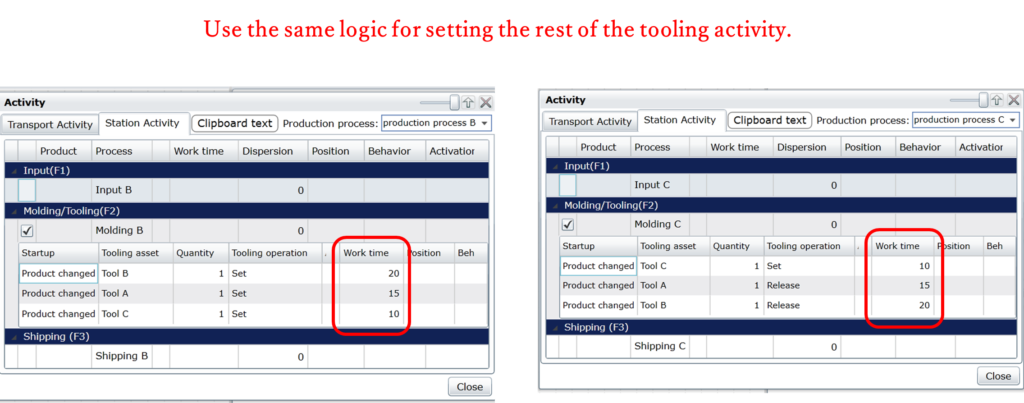

First, define the tooling activities (changeover) that occurs when changing the product. Then, the tooling activities will act as a sub-main activity at the workstation.

For example:

Product A ↔ Product B, changeover 35s

Product B ↔ Product C, changeover 30s

Product C ↔ Product A, changeover 25s

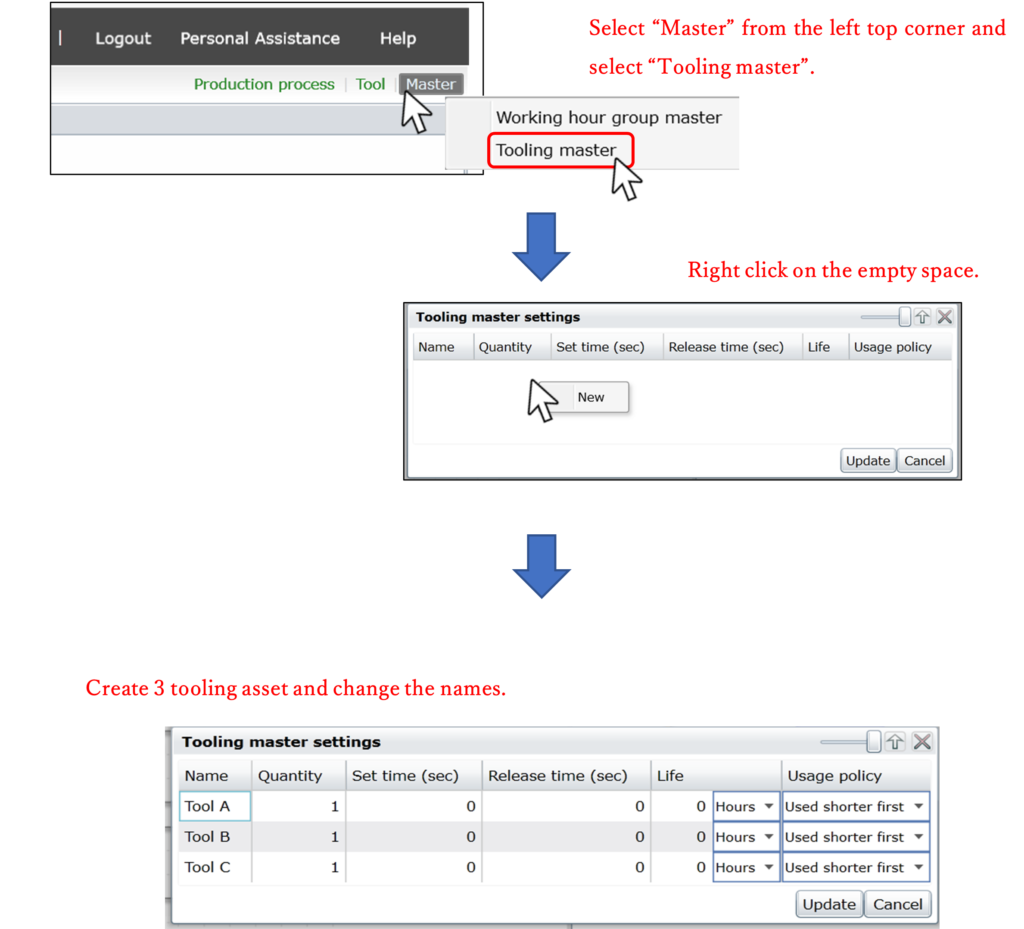

- When you want to set the changeover time like above, please add a Tooling Asset from the “Tooling Master”.

- In this case, we assume the changeover time for each tool is the same.

Tool A: 15s

Tool B: 20s

Tool C: 10s

Notes:

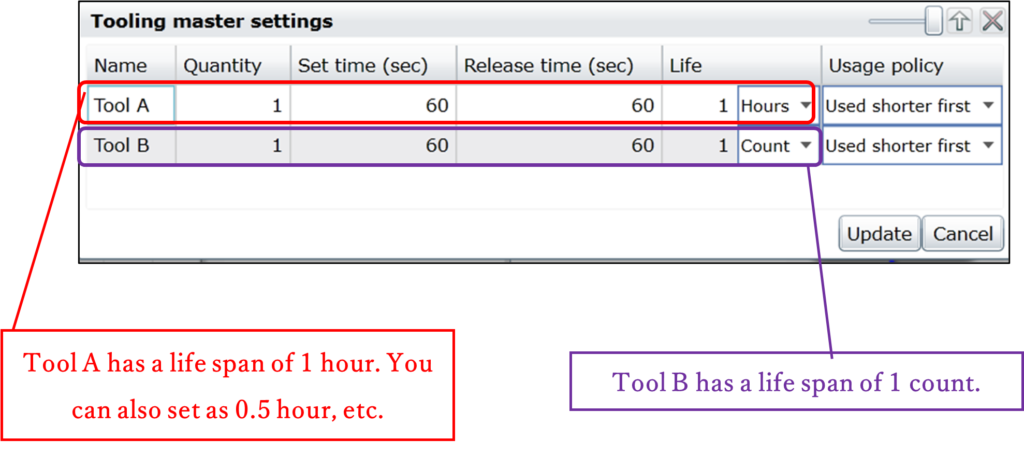

Life→ The Life function is the counts or duration of time (hour) of the process can be performed with the tooling asset attached to the station. If the process runs over its life value, the tooling asset becomes unusable. Users can define the counts or time duration as the unit of tooling asset’s life spend.

- Usage policy→ This function explains the rules when a tooling asset is assigned to a station, the usage policy can be select from [used shorter first] and [used longer first]. The following shows the selection rules when each usage policy is set.

- Use shorter first→ From the assigned tooling assets, select the one has the shorter usage time, which is the highest remaining life value.

- Use longer first→ From the assigned tooling assets, select the one has the longer usage time, which is the lowest remaining life value.

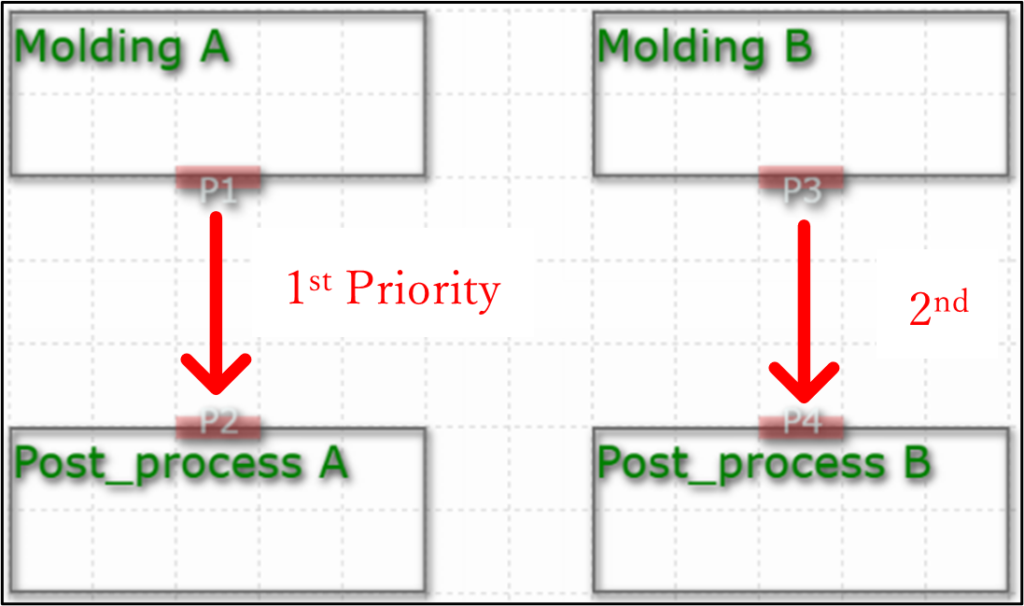

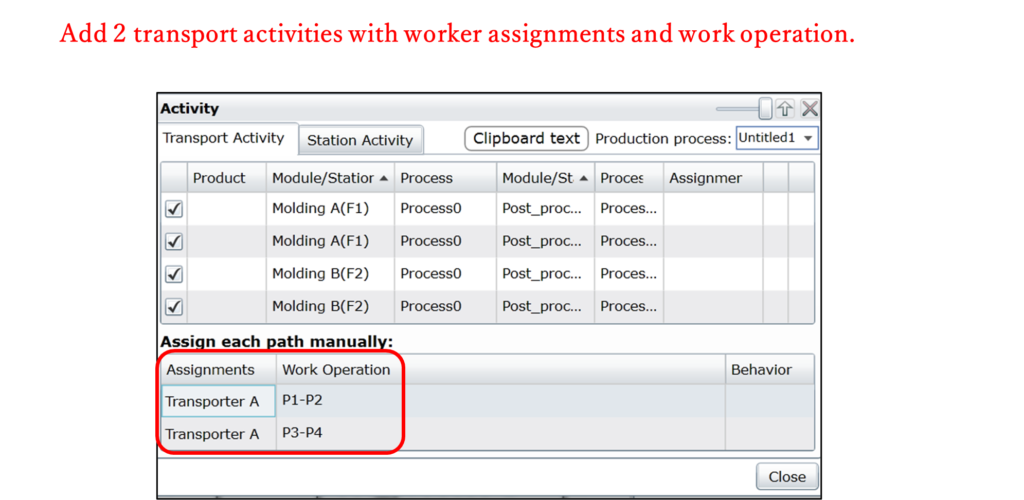

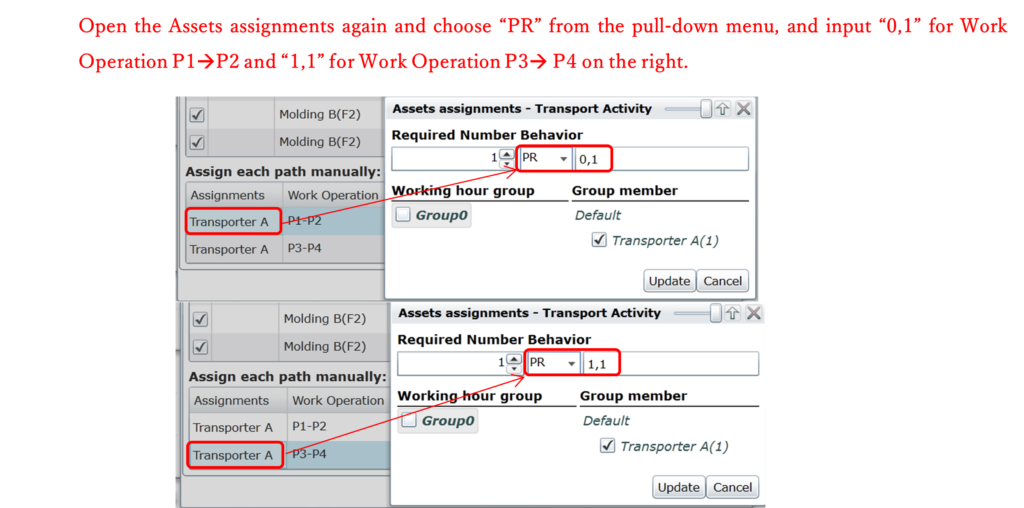

Transport activities can add a constraint to prioritize the operation order by using behavior function “PR”

For example:

There are 2 transports path in the factory floor plan.

P1 to P2 and P3 to P4, and the priority of the transport is P1→P2> P3→P4.

Note: In GD.findi, when setting the priority of operations, the 1st priority starts with “0”.

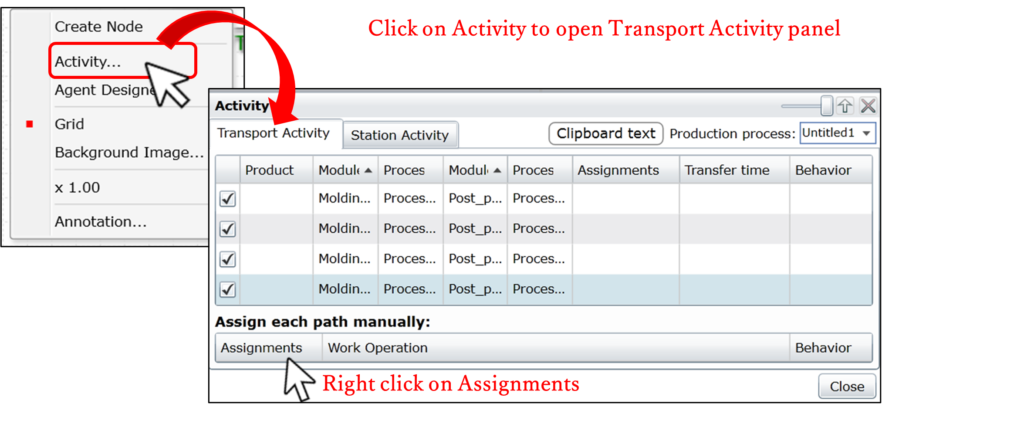

After associating work elements and workstations, please go to transport activity in Activity panel.

Note: What is PR?

PR → one types of behavior constraint that can be set in GD.findi. stands for Priority.

Input Format

| 1st input | 2nd input | 3rd input | 4th input* | |

| Input item | PR | process priority | threshold for advancing the priority order | number of sequential |

| Format | fixed | positive integer | positive integer | positive integer |

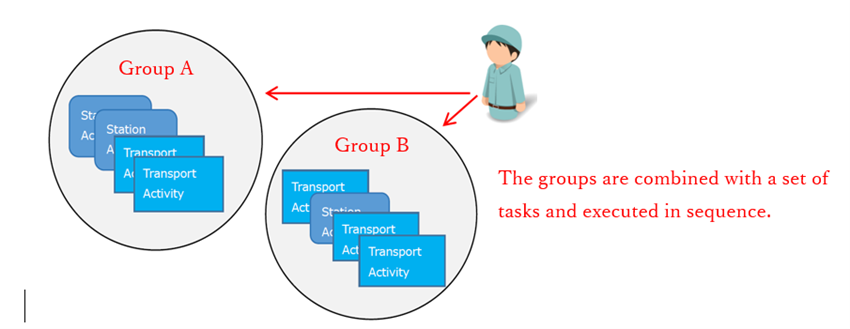

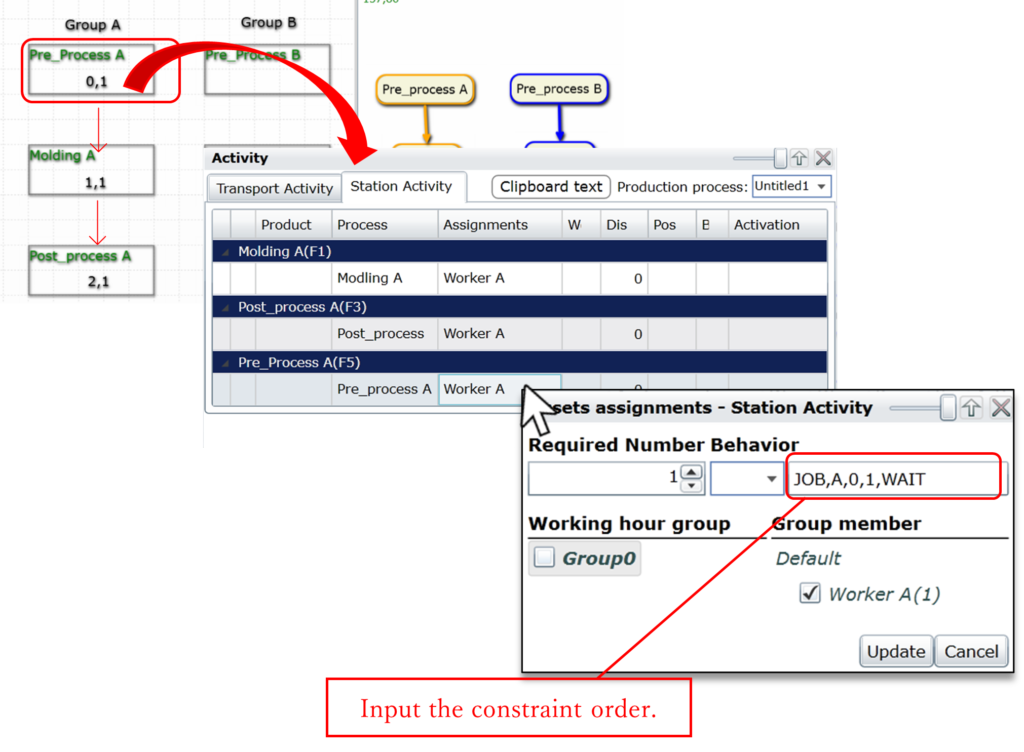

When transport activity doesn’t go the way you wanted, try to use “JOB” as a behavior constrain on the workers. This function allows you to determine the order of the transport activities in a group.

“JOB” allows for multiple groups of activities to be assigned to workers, for example, a worker can produce product as a single flow line.

“JOB” allows workers to assign to multiple groups of activities.

Input Format:

| 1st input | 2nd input | 3rd input | 4th input | 5th input | 6th input | |

| Input item | JOB | Group ID | Operation Order | Number of operations | Execution mode | Evaluation mode |

| Format | Fixed character | arbitrary character | positive integer | positive integer | Fixed character

“WAIT” “ABORT” “NEXT” | Fixed character

“TRUE” “FALSE” |

For Example: When there are two production lines, worker A is only in charge of group A production, while worker B is in charge of group B production. On top of that, the transportation tasks are prioritized within the group.

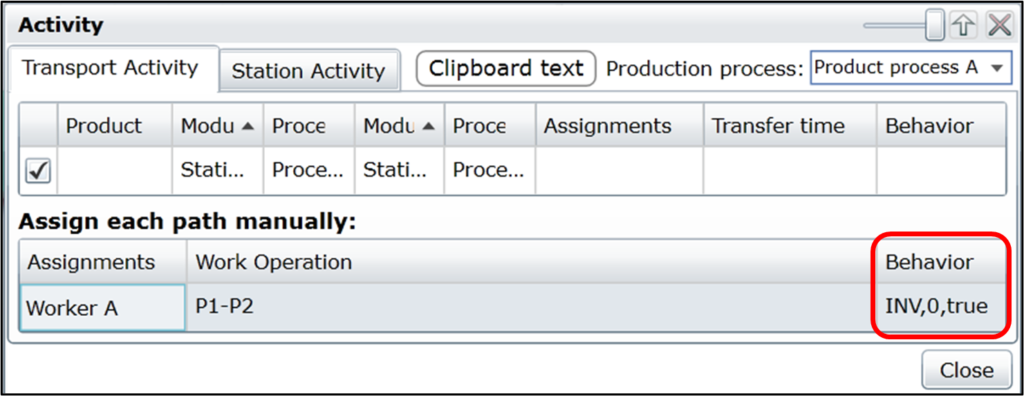

In GD.findi, there are many ways to set the transport start time, you will see 2 examples here: behavior function “INV and “FT”

①Transport Activity behaviorà “INV” (Inventory)

It defines the constraint of the transport operation considering the condition of the inventory quantity (buffer size) in the workstations.

Setting method example:

Input Format:

| 1st input | 2nd input | 3rd input | |

| Input item | INV | *Inventory condition | *Condition for loaded parts |

| Format | fixed | positive integer/ conditional expression | true / false |

Inventory condition explanation (assume the 3rd input is TRUE):

- Positive integer

The integer represents the number of inventories in the destination workstations when the transport starts. Therefore, “INV,0,true” represent if the inventories in the destination workstations is “0”, the transport operation starts.

- Conditional Expression

If the condition in the workstation satisfied the “Conditional Expression”, the transport operation starts.

Ex) [F2.COUNT=0,true]àtransport operation starts when Station F2 has 0 inventory quantity.

Condition for loaded parts explanation:

- If “true”

The transport operation will start when all the condition in workstation inventory and loaded parts are satisfied.

- If “false”

The transport operation will start when the condition in workstation inventory is satisfied and AT LEAST 1 loaded part is met.

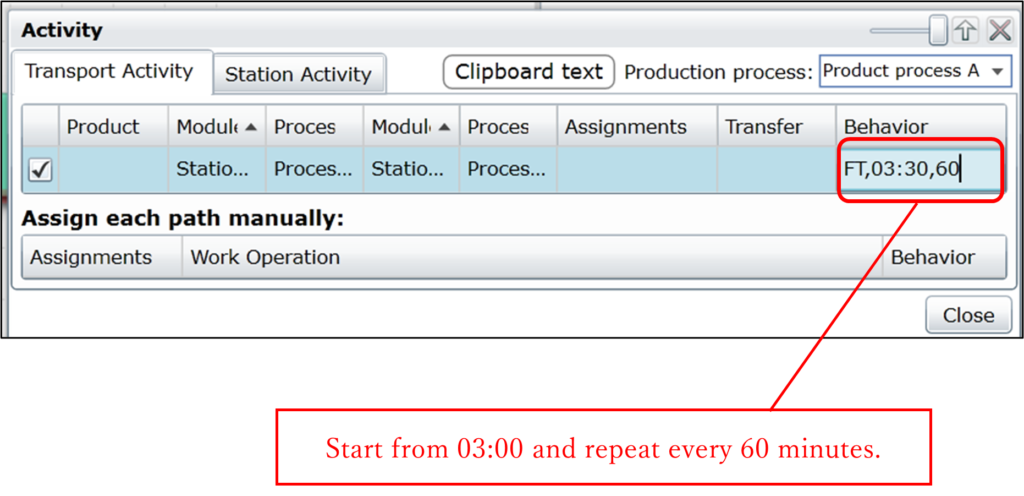

②Transport Activity behaviorà “FT” (Fixed Time)

“FT” repeats the defined transport operation at a repetition time interval from the start time.

Input Format:

| 1st input | 2nd input | 3rd input | |

| Input item | FT | Start Time | repetition interval |

| Format | fixed | HH:MM:SS or HH:MM | Integer (minute) |

Example of setting FT in transport activity:

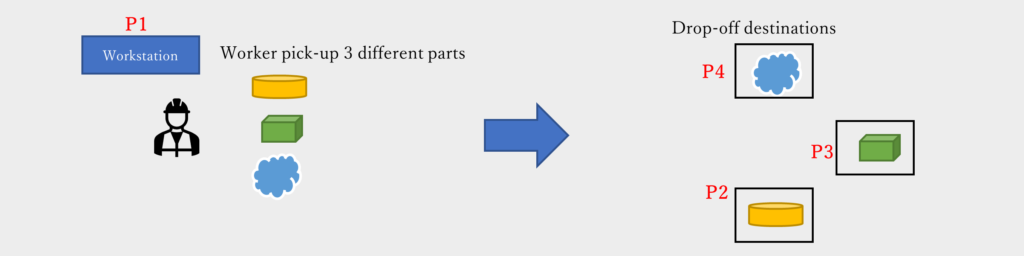

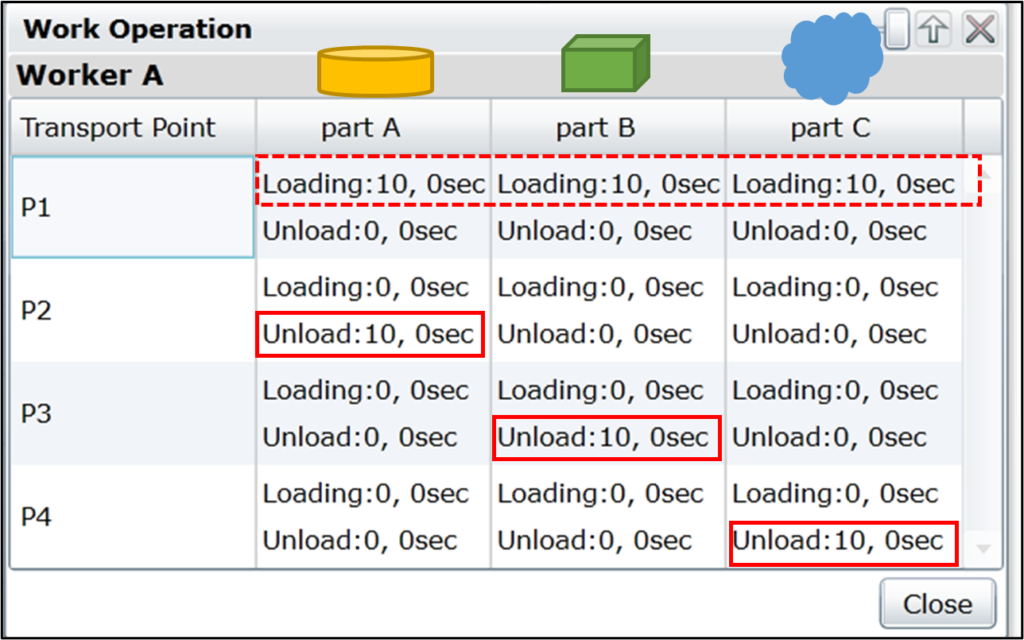

Define the parts you wish to consolidate in a transport operation from “work operation” in transport activity, then assign transporter and transport route.

For example:

The worker consolidates 3 different parts in one transport activity, and the destinations are different. Below is an example of how to define this situation.

Example setting in transport Work Operation:

Example setting in transport Work Operation:

10→quantity of part

In this case, part A/B/C are loaded at “P1” and unload at different location. (P2,P3,P4)

In GD.findi, the unit of life span of a tooling asset (changeover tool) can be defined in the form of used counts or time span. If it is defined as used counts, the life span is calculated based on how many times the process is operated; if it is defined as time span, the life span is calculated in the operating hour the process can run.