Modeling Simulation

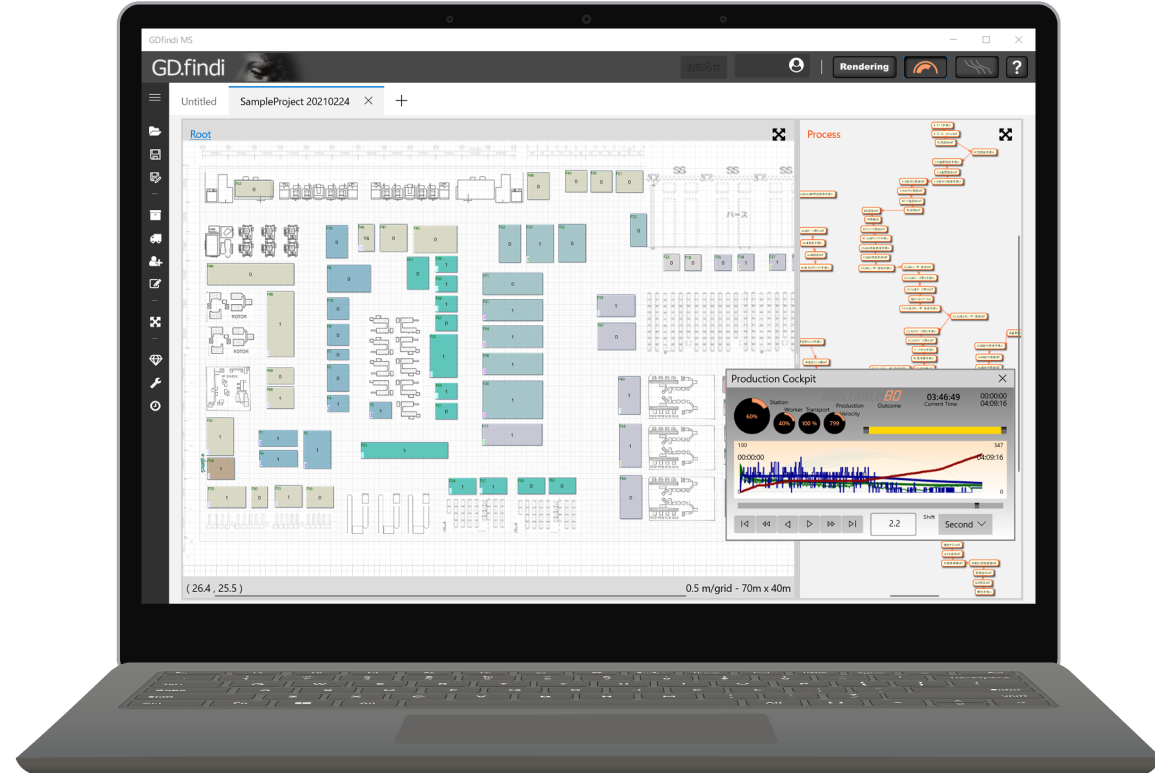

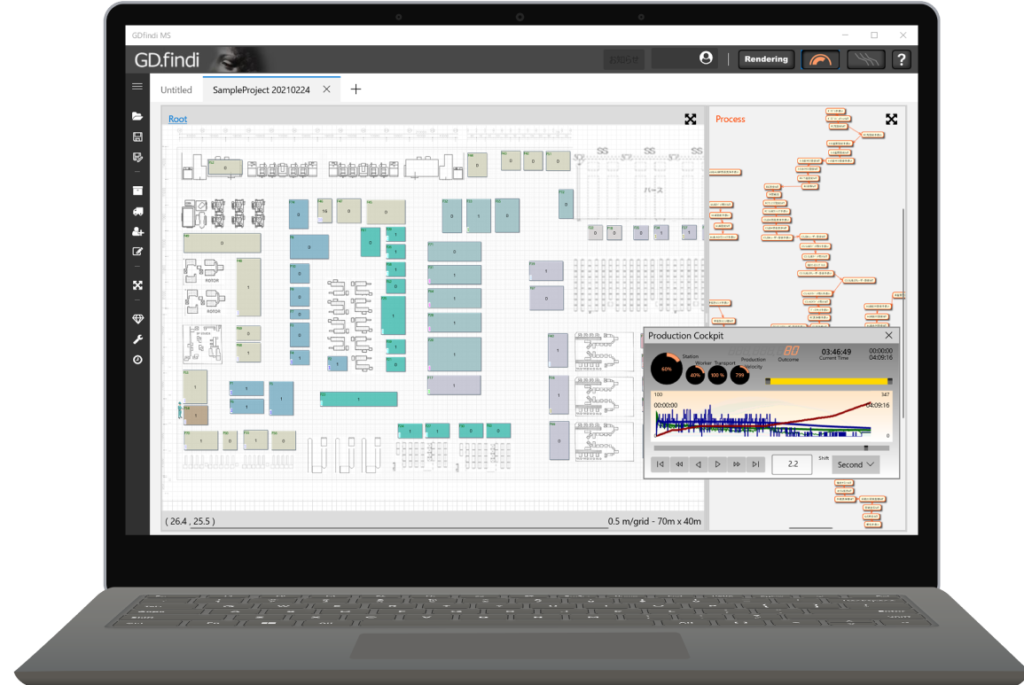

GD.findi MS

GD.findi MS provides a rapid engineering technology for every production engineer.

GD. findi is a no code, model-based production simulator unlike any conventional simulator. GD. findi’s simulations are used in a variety of manufacturing scenes, from improving existing production lines and verifying new production lines as well as optimizing production plans.

GD.findi MS provides a rapid engineering technology for every production engineer.

GD. findi is used by many manufacturing manufacturers and educational institutions.

Are you struggling with these problems?

- Designing processes for high-mix low-volume production does not work well.

- Manufacturing lead time is too long.

- A lot of in-process inventory has accumulated, but somehow there is not enough when you need it.

- Unable to proceed according to the production plan, or to respond to urgent orders.

- Unable to determine whether to invest in a new production line or equipment due to lack of clarity on the profitability of the investment.

- Designing processes for high-mix low-volume production does not work well.

- Manufacturing lead time is too long.

- A lot of in-process inventory has accumulated, but somehow there is not enough when you need it.

- Unable to proceed according to the production plan, or to respond to urgent orders.

- Unable to determine whether to invest in a new production line or equipment due to lack of clarity on the profitability of the investment.

Improving the production line requires evidence of decision-making.

In production engineering operations such as reviewing process design, renovating factory floor layout, making production and personnel plans, or introducing new factories and equipment, “data as a basis for decision making” is essential.

GD. findi MS is the best solution for such problems!

Validate your production system with simulation of GD.findi MS.

Support reasonable decision making and achieve total optimization!

GD. findi MS can be used to virtually verify production lines, floor layouts, and production and personnel plans.

The simulation results allow you to make decisions based on data and indicators that will optimize your organization as a whole.

Customer Voices

Mr. Kamiyama

Shinano Camera Co.

Highlights of GD.findi MS, a production simulator

Innovate the culture of manufacturing to the level of high economic efficiency by enhancing the art of engineering.

High productivity of engineering with GD.findi makes production simulation applicable to projects with a wide range of bases than ever before.

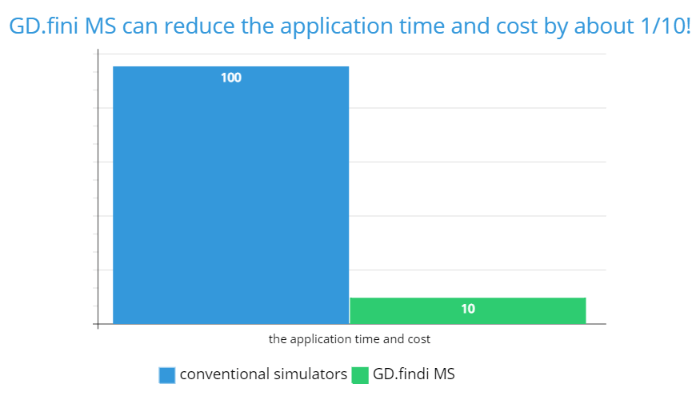

GD.findi enhances the art of engineering and generates 10 times as much economic value as conventional simulators, thanks to its applicability to implement for the wide-and-varied engineering subjects.

Conventional simulators

Its applicability was very limited, unless it was developed to suit a specific project, subject, and purpose. This special customization required a lot of cost in time and HR, which made it further difficult to publicly use simulators. This is the reason why it has been big-budget projects only that was privileged enough to use simulators: no small-scale project could afford it.

GD.findi MS

GD.findi MS does not require special development, thanks to its patented data-model technology. It helps to reduce the cost to implement a simulation dramatically – 90% less compared to conventional simulators – and represents a technology that enables a dramatic enhancement of the engineering utility. GD.findi is open, budget-friendly, widely applicable, and easily accessible to everyone, regardless of budget or engineering subjects.

GD.findi unchains simulation from the rule of its experts, and makes it a means of digital transformation for everyone to innovate production system design.

Simulation has been a privilege, used solely by the riches and IT elites. GD.findi unchains simulation from the rule of IT technocrats, and makes it a means to facilitate digital transformation of the production system design, and to enhance the qualified engineering skills.

Conventional simulators

The applicability of conventional simulators has been very limited, due to the required development by highly trained experts of IT and simulation to meet a purpose. A separate order has to be placed for this special development, which however is very costly. And this caused not only a tremendous cost and time, but untransparent communication between buyer and vendor, which often ends up creating a software, unsatisfactory for the initial purpose to use simulation for.

GD.findi MS

GD.findi MS is an answer to such problems of conventional simulators. Thanks to its patented data-model technology, GD.findi is not only able to satisfy a purpose, which a production simulation is meant to be applied for, but also easily accessible to every manufacturing professionals.

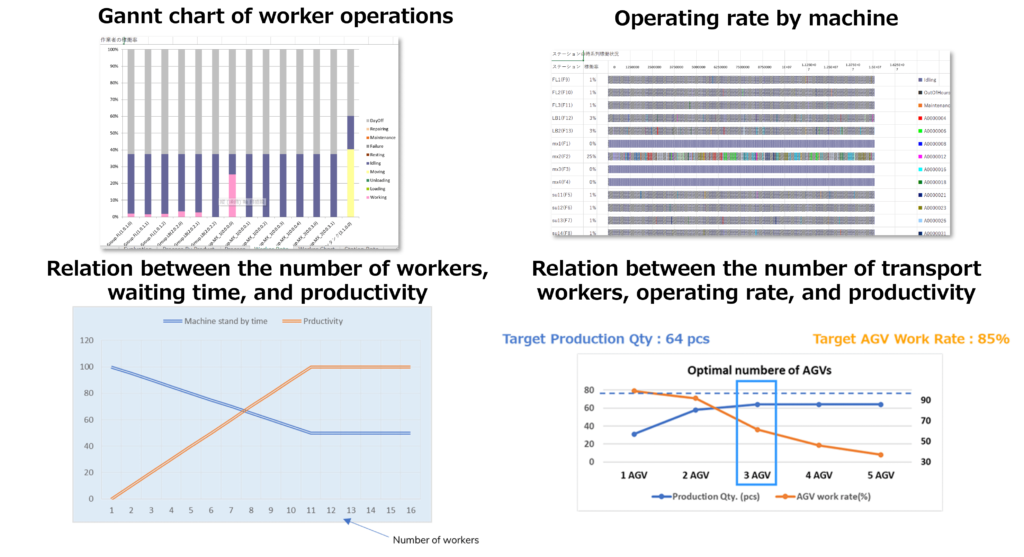

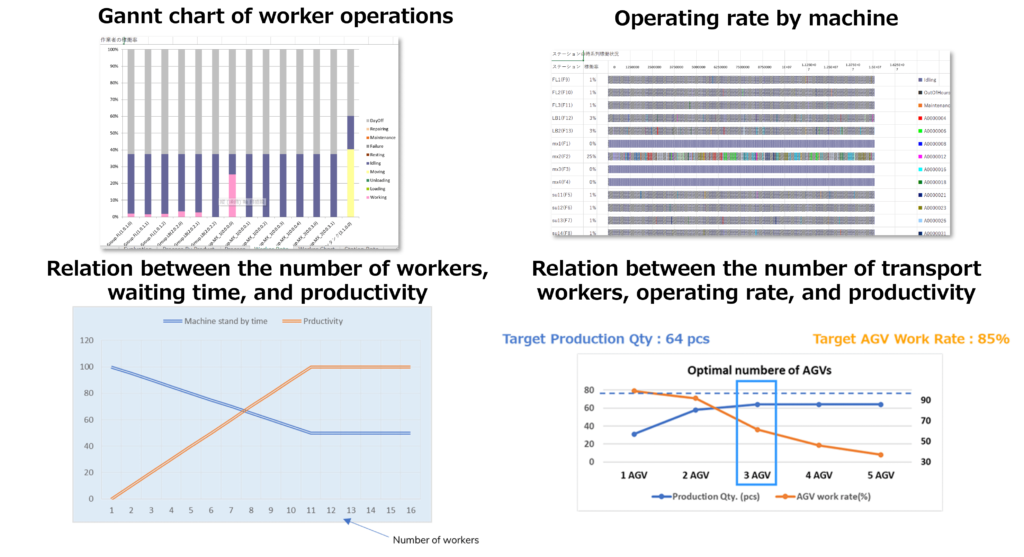

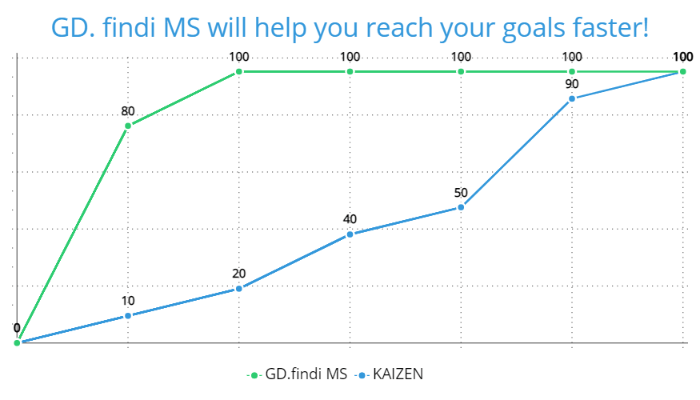

“Virtual KAIZEN” with GD.findi helps to accelerate the development of Lean Manufacturing and maximize the production capability with intuitive and interactive iteration.

GD.findi can create “KAIZEN” plans, and implement them at virtually-created production site as many times as necessary. It helps, even from the pre-design planning phase of project without anything but ideas, to develop a master plan of lean manufacturing, and maximize the production capability.

Traditional Kaizen

“Traditional Kaizen” has been a key methodology, which has sustained a competitive manufacturing culture in Japan. However, its limit was always clear: not possible to implement any “Kaizen” agenda without something real, like onsite machines. Thus traditionally, “Kaizen” has been planned and developed only after production is ready and running, simultaneously observing the production status. It was not expected to achieve the best of best to maximize the production, but something no more than realistic for a good deed of effort and time.

GD.findi MS

GD.findi can embody the Kaizen ideas to improve the overall performance of production in the reliable shape of simulation, aimed to develop further lean manufacturing.

*Lean Manufacturing is meant to produce – provide – the best value for customer with the least cost, by means of strict and efficient control of the value flow, which is aimed to get rid of waste of any kind.

Functions of GD.findi MS

By inputting data from process charts, MBOM, CAD drawings, production plans, work control charts, etc. into GD. findi and running simulations, you can output indicators that can be used for various kinds of verification and analysis.

- Cloud

GD. findi MS simulation data can be shared in the cloud, enabling timely information sharing with other sites. It can also be used regardless of the IT environment, as it does not require the company to prepare its own server.

- Services & Support